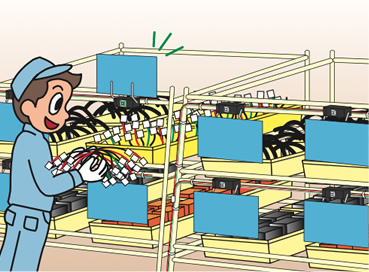

Application 1 Take-out

“High-mix and low-volume production” is typically the case at current production sites, and “take-out” is inevitably a major point to increasing production efficiency and stabilizing product quality.

“High-mix and low-volume production” is typically the case at current production sites, and “take-out” is inevitably a major point to increasing production efficiency and stabilizing product quality.

Adoption of the POKAYOKE terminal can significantly reduce work manhours, eliminate errors in take-out of parts and also reduce worker stress.

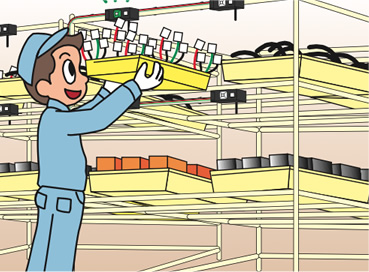

Application 2 Throw-in

“Throw-in” always exists at production sites where “Take-out” exists.

“Throw-in” always exists at production sites where “Take-out” exists.

The POKAYOKE terminal is also used to prevent errors in “Throw-in” of parts.

Adoption of the POKAYOKE terminal can secure confirmation of throw-in of parts. It is recommended to introduce the POKAYOKE terminal for “throw-in” in conjunction with “take-out.”

Application 3 Cell production

The “cell production” method has become more common at production sites of “High-mix and low-volume production.”

The “cell production” method has become more common at production sites of “High-mix and low-volume production.”

In this method in which one worker is in charge of the initial to the end of the assembly process, there are multiple processes, and if the worker makes any mistake, it is hard to make up for it.

Very small type which can be installed at a narrow opening and the end surface of a column plate is available in the POKAYOKE terminal lineup, and is also most suitable for cell production.

Application 4 Kitting: Tray service

Work in which parts which are necessary for manufacturing of a certain product are collected in one box (kit box) as one kit is called “kitting.”

Work in which parts which are necessary for manufacturing of a certain product are collected in one box (kit box) as one kit is called “kitting.”

The ultimate objectives of the take-out process and kitting are the same, however, detailed work instructions such as quantity and sequence of take-out are required for kitting.

POKAYOKE terminal is also used at such kitting sites.

▲ PAGE TOP