Advantage of AnyWireASLINK

1. Increase in space efficiency by downsizing of I/O terminal

- Before

- Replaceable type jig is used. Downsizing is attempted by ingenuity of design, however, the relay box is bulky and downsizing cannot be achieved as expected.

In order to respond to a wide variety of products, freedom of design is also necessary, and it is desirable to simultaneously save energy by downsizing and weight savings.

- After

- ASLINK is a very small terminal comparable to a relay connector.

Since ASLINKER is directly installed to a cylinder, a relay box for sensor wiring can be removed, and downsizing and weight saving can be realized.

- Video introduction from here →

Click to replay video on other window

*Text of the video is all Japanese

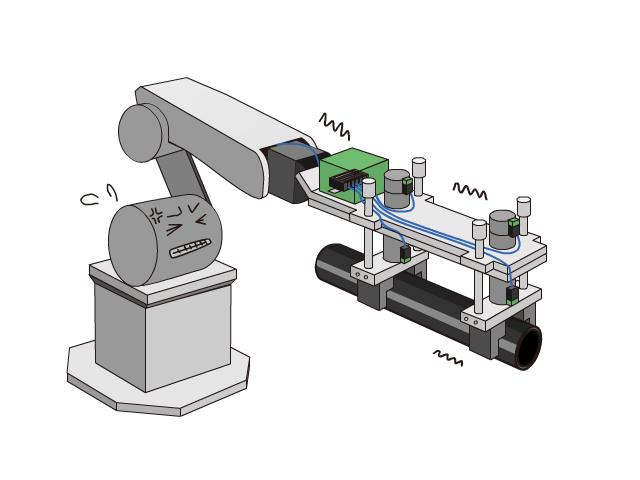

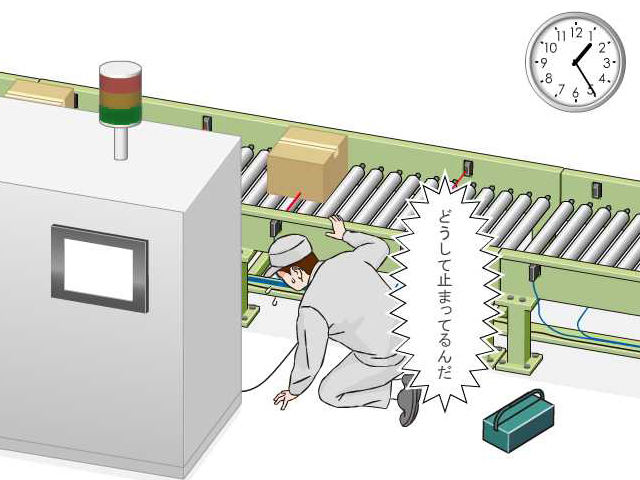

2. Investigation of cause by disconnection detection function for sensor cable

- Before

- ID (address) which should turn ON at a determined timing is not turned ON and the equipment stops.

- Is the sensor in failure? - Is the mechanism part in failure?There are various causes as to why the sensor is in OFF status, and confirmation and inspection with input which cannot be judged on the controller side are essential. This means that an investigation into the cause will take many hours.

- Is the terminal in failure? - Is the wire disconnected?

- After

- Disconnection detection function for sensor cable mounted on ASLINKER can significantly reduce time spent on investigation of cause.

Monitoring is also facilitated by combination with GOT, and a highly visible monitoring system is allowed to be built.

- Video introduction from here →

Click to replay video on other window

*Text of the video is all Japanese

3. Preventive maintenance by sensing level monitoring

- Before

- The typical sensor judges ON and OFF on a threshold boundary and outputs a signal.

Therefore, the typical sensor cannot detect a drop in actual sensing level etc., (such as deviation of light axis and adherence of dirt) and suddenly stops operation at the instant when the sensing level falls below the threshold.

- After

- ASLINKSENSOR always monitors sensing level of a sensor.

The sensing level is converted into digital data, which is transmitted to a higher controller and is monitored by GOT, therefore, preventive measures such as replacement, adjustment and cleaning can be taken before “the sensor can be turned ON.”

- Video introduction from here →

Click to replay video on other window

*Text of the video is all Japanese

4. Reduction in adjustment production steps and man-hours by sensor sensitivity setting function

- Before

- Sensitivity setting of each sensor and recording of set values to ensure traceability are, in general, manually performed even today. Therefore, both setting and recording required a large number of man-hours over many hours.

- After

- ASLINKAMP and ASLINKSENSOR allow the sensing level to be adjusted from a higher controller and also allow current set values to be saved. On the other hand, they also allow the saved set values to be refiected onto each sensor, resulting in significant reduction in man-hours. In addition, momentary stop can be prevented by adjustment of threshold to control maintenance timing.

▲ Page top